FindItMore | Before using the sanitary pumps in your project, there are a few essential things you should consider. Consideration of these things will help you to purchase the best quality pump that perfectly matches with your project requirements. Well, here we are listing these crucial factors in the form of questions-answers. Without taking your more time, let’s start the discussion:

Q 1: What is the use of sanitary pumps?

The sanitary pumps are basically used to transport the colloid of food material in operation, for example, food processing that demands cleanliness. To perform this task, various kind of sanitary pumps are fabricated. All has its own feature and perform a specific task for the users.

Q 2: What are the specific features of sanitary pumps?

When it comes to feature parts, these pumps have much more to offer you. These are available with a bundle of outstanding features that make them the best option to choose. These are available with the adjustable speed; it means you can operate the speed of the pump on your own.

- Next, the significant feature is 100% duty cycle. The duty pumps sustain performance specifications at a 100% duty cycle.

- You can find many wastewater pumps that comprise a grinding mechanism, level control device, pressure gage, backup battery, thermal overload protection, strainer, filter, control panel, or suction.

- By operating the Run dry pumps, you don’t need any lubricant or external fluid.

- Sanitary pumps can move media either horizontally or vertically, as per the direction of the pump stator assembly.

Or in other words, we can conclude these features as follows:

- Discharge flow

- Highest discharge pressure

- Media temperature

- Discharge size

- Inlet size

These are a few vital specifications about the pumps!

Q 3: What are the basic types of sanitary pumps?

The basic type of the pumps is 4, i.e.

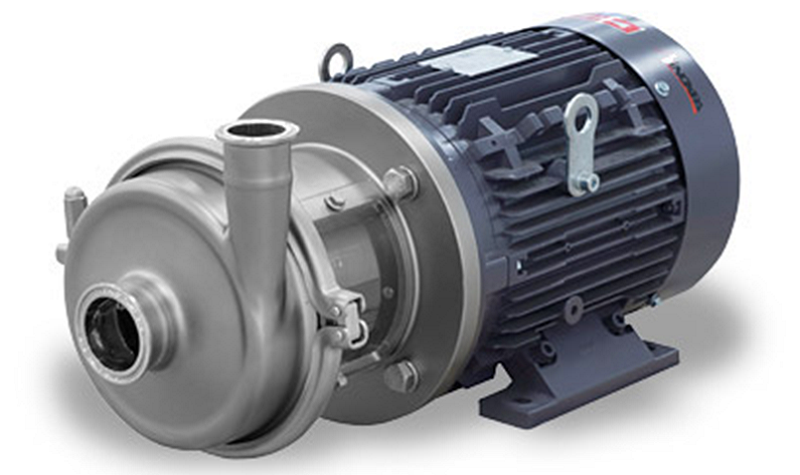

- Centrifugal Pumps

- Positive Displacement Pumps

- Jet Pumps

- Airlift Pumps

Other than that you can find the Rotary Lobe, Circumferential Piston Air operated pumps also.

Q 4: In what way the sanitary pumps work?

The major function of the pumps is moving the fluid. Now, this task is performed in various manners. According to the standard report published by the Hydraulic Institute www.pumps.org; this movement is done as per the method energy is imparted to the liquid: positive displacement (PD) pump or kinetic energy pump.

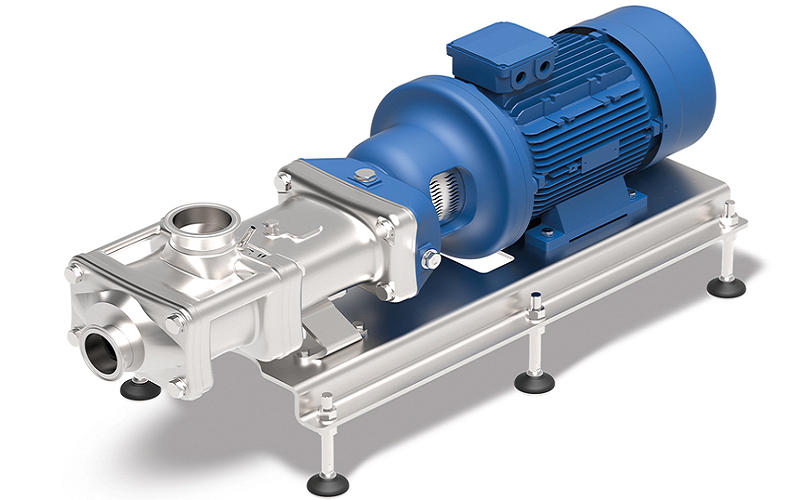

- Positive Displacement (PD) Pumps:

Flexible impeller, double-diaphragm, bellows, progressing cavity, rotary vane, piston, oscillating, gear, rotary lobe, and peristaltic pumps have a cavity that the fluid is pressed through by different means such as gears, impeller or rollers. As the fluid is pressed, it leaves a vacuum.

- Kinetic energy type:

Next type is Kinetic energy type. In this type, the pumps pass on the energy to a liquid with the help of centrifugal force. Now this force is generated by a disk, rotating impeller, or another blade form. Centrifugal pumps are designed in many shapes, sizes, and forms.

Q 5: What kind of pump is used for pumping Hot Wort?

For pumping the hot wort, usually, the stainless steel Centrifugal Pumps are used. Whereas if we consider the case of brewing pump, it needs to be able to manage the suspended solids within the wort, be capable to oppose the temperature of the fluid and have the secured and powerful mechanical seal.

Q 6: When using a Positive Displacement Pump and Centrifugal Pump provide the best outcomes?

Positive Displacement Pumps:

The Positive Displacement Pumps usually employed in the brewing industry. The primary function of such pumps is to transfer thick fluids with high solids concentrations at superior pressures with comparatively little flow rates. The best examples of applications are:

- Liquid Sugar Transfer

- Bottling, Casking & Canning

- Mash-in-Wort

- Syrup Transfer

- Yeast Slurry Transfer

- Mash Recirculation

Sanitary Centrifugal Pumps:

This kind of pumps is mainly used in the brewing industry. The best uses of this type of pumps are for transferring the low viscosity fluids at high volumes and relatively low pressures. The best examples of applications are:

- Tank to Tank Transfer

- Hot Wort Transfer

- CIP pumping & scavenging

- Hot Liquor Transfer

- Tank cleaning

This is the list of most frequently asked questions along with reliable answers about sanitary pumps or Sanitary replacement Parts. This list will assist you in terms of finding the best pumps and understand its working process. For more updates, stay tuned!